Four Advantages of Haochen

Customized for heating channel systems for plastic molds and injection plants for plastic products

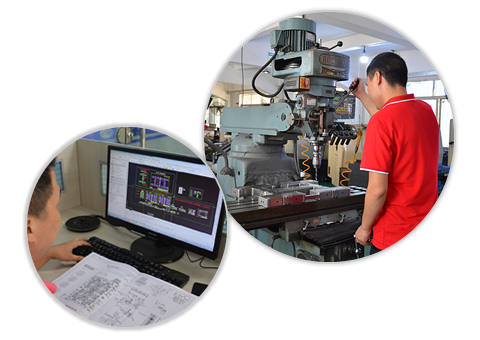

20 years of rich experience

● 20 years of industry experience in designing needle valve hot runner for daily necessities molds, electronic molds, and automotive molds

● There is a high demand for product appearance, and it is necessary to adjust the amount of glue injection to solve technical problems such as no residue, no material mouth, no printing force mark, flat sealing, and multiple glue mouth injection without a bonding line. I have rich experience in this field.

● Dozens of processing equipment, including 5 imported precision high-speed lathes and 3 Mazak machining centers.

International standard components with stable quality

● Achieve industry leadership to a minimum of 9mm with a spacing of 17mm

● 8More than 00 successful customer cases, and Nuojin has a unique patent for 500 mold times without changing the mouth.

● Copper sleeve heater increases heating speed by 60% and saves 1/3 of electricity bills.

● The durability of the needle valve hot runner ensures no glue leakage for 5 million mold cycles, and many customers even achieve no glue leakage for more than 10 million mold cycles. Produce more products, reduce mold opening, reduce downtime, and increase efficiency.

Large quantity of stock, fast delivery time for customization

● Sample production takes 3-7 days, batch production takes 7-10 days to deliver

● Over 200 square meters The warehouse keeps stock all year round, and universal related products are delivered to customers in the province within 1 day. In emergency situations, they are delivered by car.

● I have over 10 years of experience in plastic products such as daily necessities, small household appliances, medical equipment, etc. that require high surface requirements and require no spraying.

Provide personalized technical support services

● Haochen products promise a 3-year after-sales warranty and lifelong technical support services!

● 3 Second response, arrive within 3 hours in the Pearl River Delta region and 8 hours nationwide.

● Pre sales success case explanation, technical installation and usage training!

● Provide plan diagrams and 3-hour model flow analysis reports within up to 2 hours

What services can we provide for you

Injection Product Design - Precision Injection Mold - Injection Molding -24 Hour Online Aftersales Service

Quality control · Strength

Master the core process and strictly control the layers of plastic mold processing processes

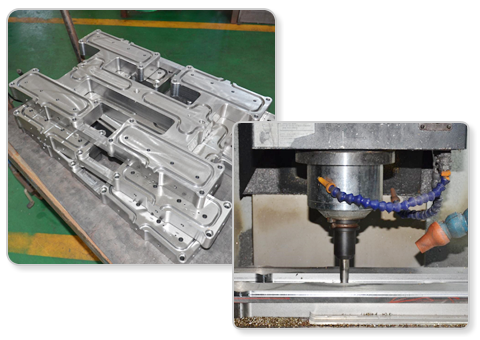

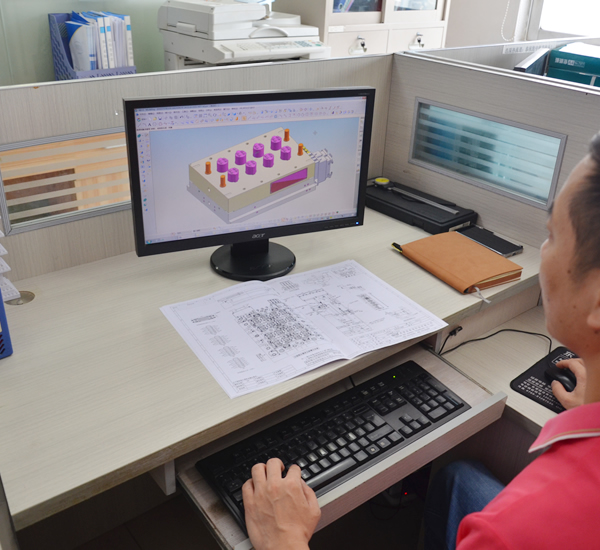

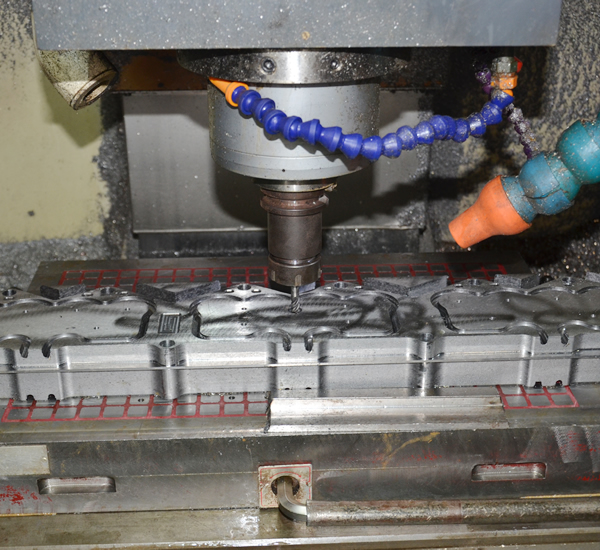

Precision mold manufacturing equipment

Precision mold manufacturing equipment

The high-end quality must be precision mold manufacturing, and the injection mold factory has precision mold manufacturing equipment internally, which can control the precision tolerance value of customer accessories to 1 wire.

Dedicated quality control team

Dedicated quality control team

We have a dedicated quality control team and engineering technology team with over 20 years of experience. During the production process, we strictly follow the quality management system as the standard, and every product undergoes strict full inspection, meeting national testing standards.

8 Strict Quality Control Links

8 Strict Quality Control Links

From material selection ->production ->inspection ->delivery ->strict monitoring at every step, every process is fully inspected to ensure that the product qualification rate reaches 99%

Cooperation · Service brand

20 years of experience in cooperation with top 100 brand merchants, long-term cooperation with top 100 enterprises such as Samsung, Xiaomi, and Midea

News · Information World

Learn more about the value of mold injection molding

2023-11-02

2023-11-02

Equipment that ensures automatic operation of hot runner molds, such as robots or easily controllable robotic arms: 1. The product needs to be placed with inserts, labels, or sheets in the mold……

.jpg)

.jpg) A 256 stacked die multi head open hot runner system for battery cover

A 256 stacked die multi head open hot runner system for battery cover.jpg) One out fifteen open hot runner system for keyboard buttons

One out fifteen open hot runner system for keyboard buttons.jpg) One out six open hot runner system for keyboard cover

One out six open hot runner system for keyboard cover澆口熱咀-800.jpg) LPG type point gate hot nozzle

LPG type point gate hot nozzle點(diǎn)澆口多頭熱咀-800.jpg) MPG square side gate multi head hot nozzle

MPG square side gate multi head hot nozzle型側(cè)點(diǎn)澆口多頭熱咀-800.jpg) MPG circular ring type side gate multi head hot nozzle

MPG circular ring type side gate multi head hot nozzle

Precision mold manufacturing equipment

Precision mold manufacturing equipment Dedicated quality control team

Dedicated quality control team 8 Strict Quality Control Links

8 Strict Quality Control Links

Mobile: 13712972461

Mobile: 13712972461 Tel: 0769 85478528/400 0988 117

Tel: 0769 85478528/400 0988 117 Fax: 0769-85478508

Fax: 0769-85478508 Email: sales@hostar888.com

Email: sales@hostar888.com Website: zgqjjn.cn

Website: zgqjjn.cn Address: No. 11 Zhenlang Road, Wusha Caiwu Industrial Second Road, Chang'an Town, Dongguan City

Address: No. 11 Zhenlang Road, Wusha Caiwu Industrial Second Road, Chang'an Town, Dongguan City